Shot Blasting

Crystal Soda Blast is a full-service prep contractor for flooring industry. We scrape, scarify, grind and/or shot blast to prep your floor for either a coating or a sealer. If you just want a simple stain and/or seal we can do that. If you need a more heavy duty coating such as waterproof or epoxy we can recommend some great experts that we've been working with for years.

Visit our projects page to see what Crystal Soda Blast can do for you.

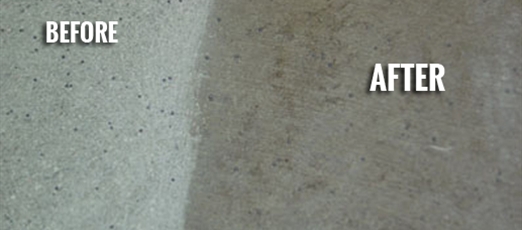

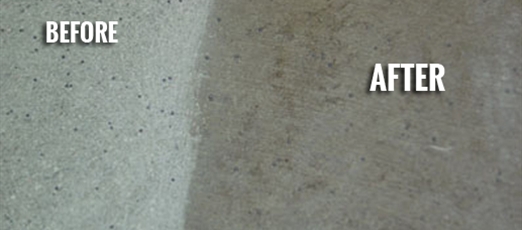

What is shot blasting? Shot blasting is an environmentally friendly and cost effective method for preparing concrete, steel, and asphalt surfaces. This labor and time saving process strips, cleans and profiles simultaneously.

Shot blasting leaves the surface immediately ready for the application of coatings or overlays, eliminating drying time and costly disposal procedures associated with other surface preparation methods. Shot blasting produces the highest bonding character of any surface preparation method.

Typically shot blasting is used in: concrete repair and restoration, general construction, flooring, painting & coating, bridges & highways, airports, remediation, demolition & renovation, utility, marine/shipyards, storage tank maintenance and others.

How does it work? CSB uses a walk-behind shot blasting system which uses a high performance, airless, centrifugal, wheel for propelling blast media at a high velocity, in a controlled pattern and direction.

Metal abrasive (steel shot- little metal balls) thrown by the rapidly rotating blast wheel is accelerated towards the surface being prepared. The media strikes the surface and rebounds, along with removed contaminants, into a recovery chamber or separator. The dust collector removes pulverized abrasive, dust, and contaminants. Very little abrasive is lost and the usable media is returned to the storage hopper for re-circulation by the blast wheel. Different surface profiles can be achieved by varying shot size, shot flow rate and machine travel speed.

Scarifying is another part of the shot-blasting and surface preparation process that uses high-speed, rotating metal or carbide disks. Scarifiers are typically used for repairing common slab problems, for example: curled joints, high spots, uneven slabs, trowel marks, damage due to weather, and other similar types of damage.

Here are some examples of scarifying:

Types of surfaces

Cement / Steel Decks / Asphalt

Do you have a Small Project That Needs Blasting?

If you have a movable item to blast such as a car or small boat, we recommend taking it to one of the local blast booths.